Product Description

Description

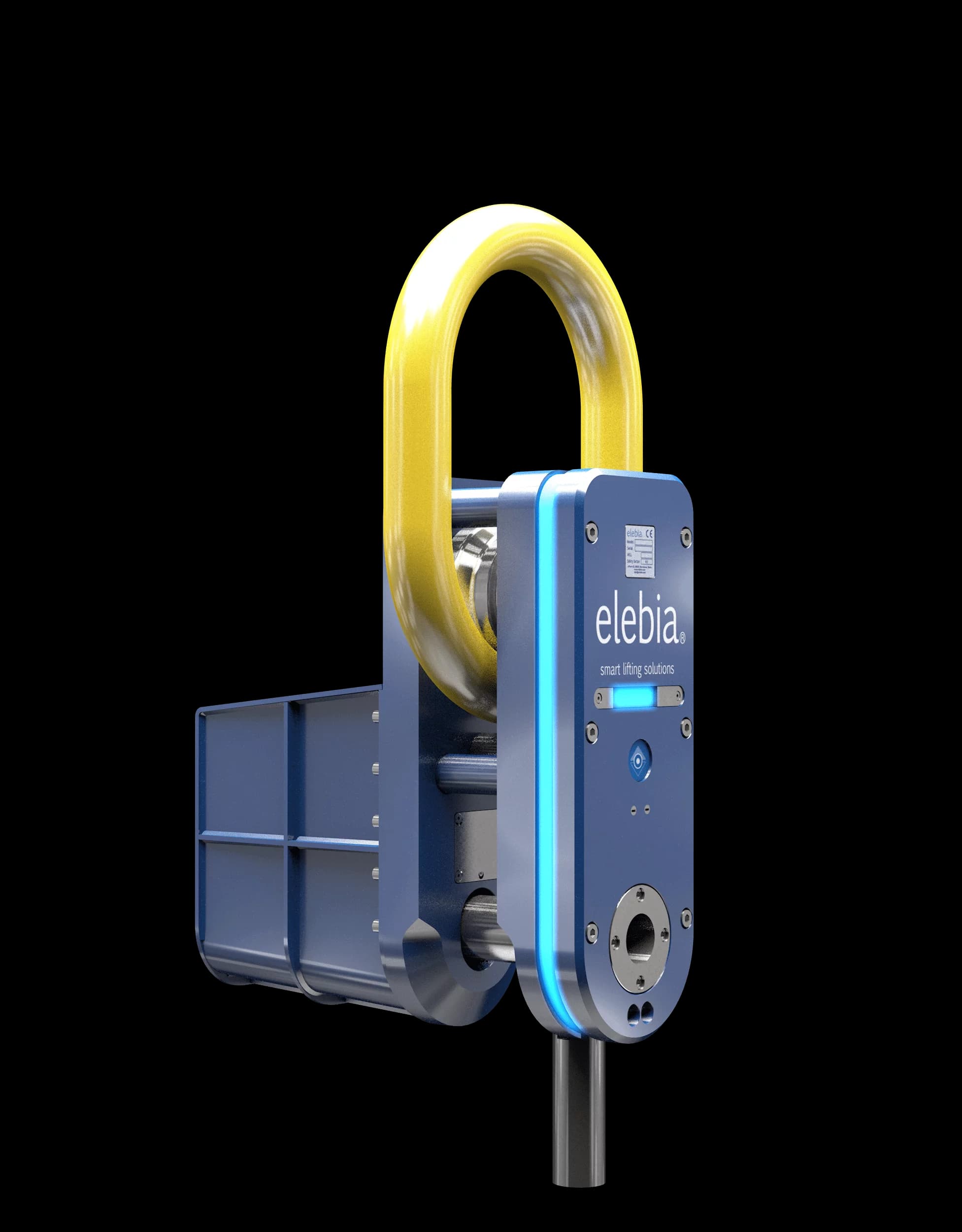

Introducing the Elebia Automatic Shackle, engineered to remotely hook and release any load with precision and ease. Leveraging its unique geometry and an innovative magnetic system, the S40 effortlessly aligns and connects with the load, enhancing operational efficiency. Equipped with advanced safety and productivity features, this industrial shackle guarantees reliable performance, setting a new standard in lifting technology.

Prose

Revolutionizing Lifting Operations: Automatic Shackle Overview

The S40 Automatic shackle is designed to deliver safe and effortless performance in industrial lifting applications. Imagine being able to engage and release heavy loads with the push of a button, eliminating the need to put workers in harm's way. That's precisely what the S40 automatic shackle offers. It also boasts a range of advanced safety and productivity features, including a LED status indicator, an auto-close system, and a safe release indicator. These features ensure reliable performance and establish a new benchmark in lifting technology.

Enhanced Safety

Eliminates the need for workers to be near the load during engagement and release, reducing the risk of accidents.

Ease of Use

Intuitive design and remote control allow for simple and precise operation.

Increased Efficiency

Speeds up lifting operations, saving time and boosting productivity.

Versatility

Ideal for a wide range of industrial lifting applications.

Fail-Safe Design: Ensuring Safety in Every Lift

To ensure the automatic shackle operates as a failsafe device, the load-bearing pin is mounted within a floating sub-frame. When the load is suspended, this sub-frame sinks into the main frame, securely locking the pin in place. This design makes it impossible to retract the pin while the load is suspended, ensuring reliable and safe operation.

Highlights

Safe Release System: Controlled and Secure Lifting

A sensor monitors the position of the floating sub-frame, with LEDs signaling when the pin is in the neutral or “sweet spot/safe release” position. Only then will the shackle attempt to release the load, ensuring a secure and controlled operation.

Effortless Lifting: Autoclose System Explained

The autoclose system combines magnets, sensors, and ingenious engineering to make remote engagement and release of loads possible with precision and safety.

Real-Time Monitoring: LED Status Indicator

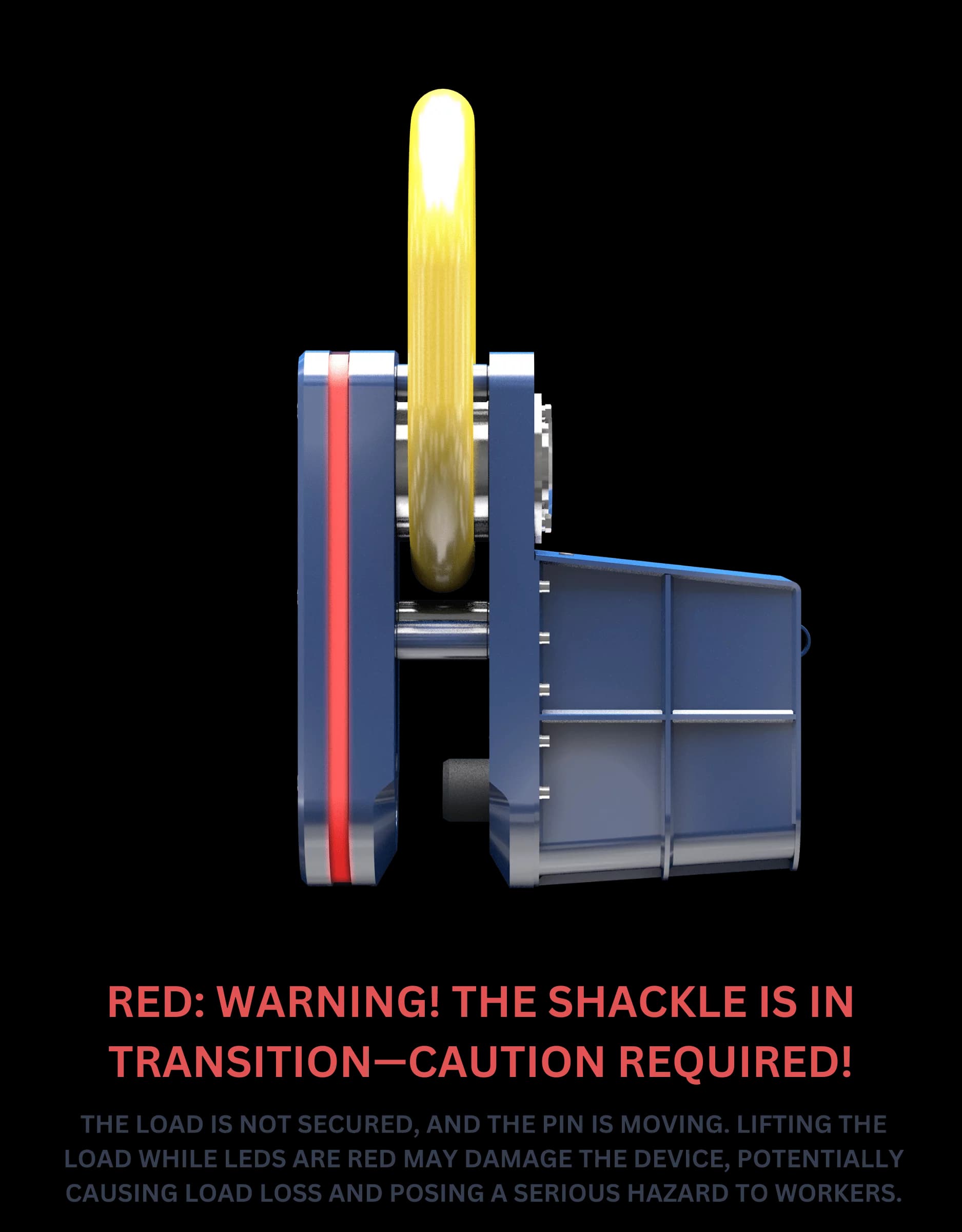

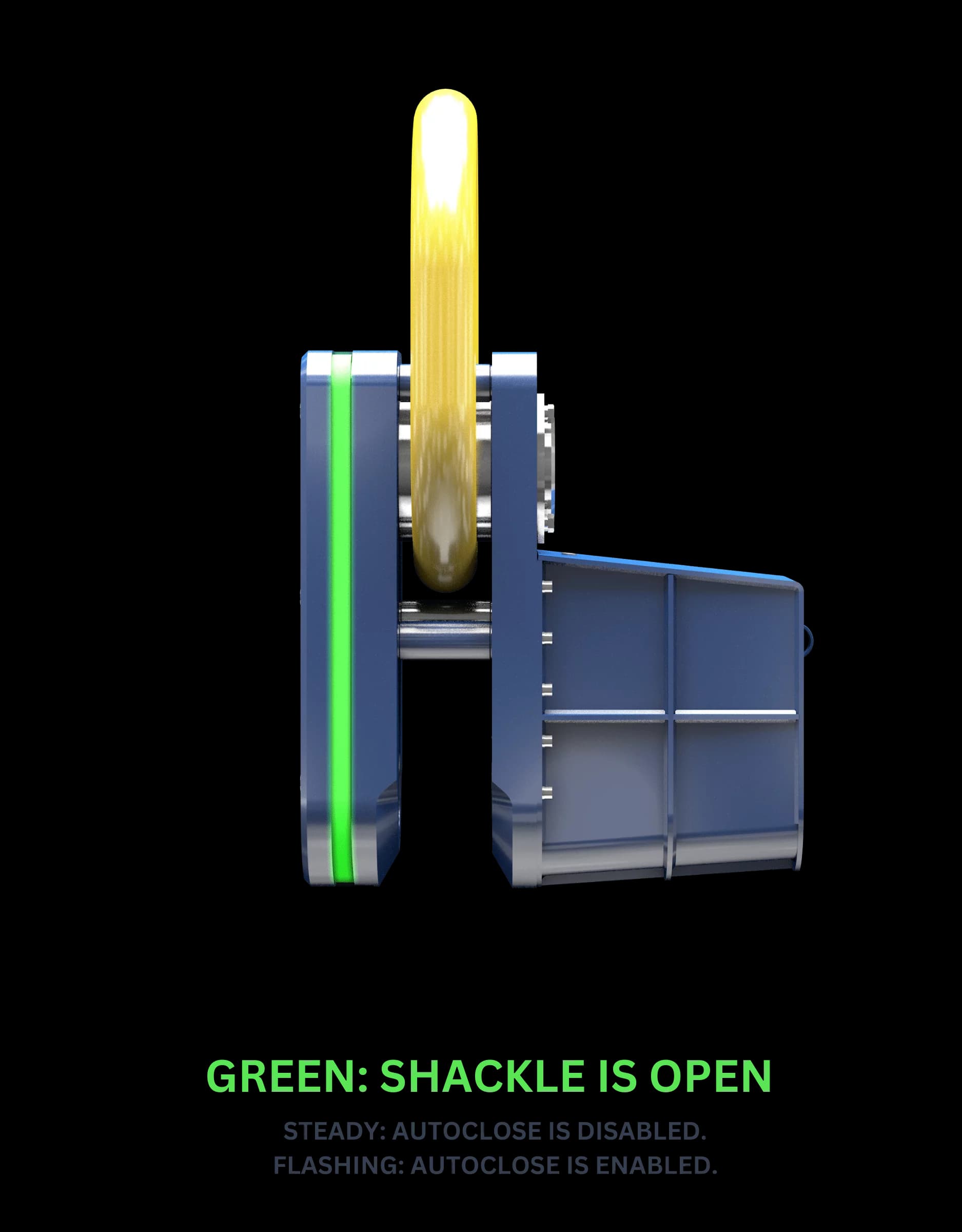

The color of the LEDs indicates the state of the hook. Green: D10 is Open / Unlocked Red: Transitioning: Watch out! Load about to drop. Blue: D10 is Closed / locked White: Low Battery

Easy Installation: Plug and Play Automatic Shackle

The shackle requires no installation: it is remote-controlled and powered by a removable, rechargeable battery.

Powerful and Long-lasting: Automatic Shackle Battery

The Battery Indicator, featuring four high-brightness LEDs, clearly displays the battery level.

In addition, the S40 LEDs turn white when a battery replacement is necessary.

Battery Life and Charging

| Operation Type | S40 (EVO-1700) | S40 (EVO-1700-3_5AH) | |

|---|---|---|---|

| Charging Time | Using Elebia charger | 3 hours | - |

| Standby Time | Device is on and idle; no opening or closing. | 120 hours | 144 hours |

| Continuous Operation | Device continuously opens and closes without rest. | 1052 cycles/ 52h | - |

| Combined Use | Device performs a full open/close cycle every 3 minutes. | 301 cycles/ 15h | - |

- Tests performed at 20ºC.

- Cycle count may vary depending on the weight being released.

- Radio consumption may vary depending on radio settings.

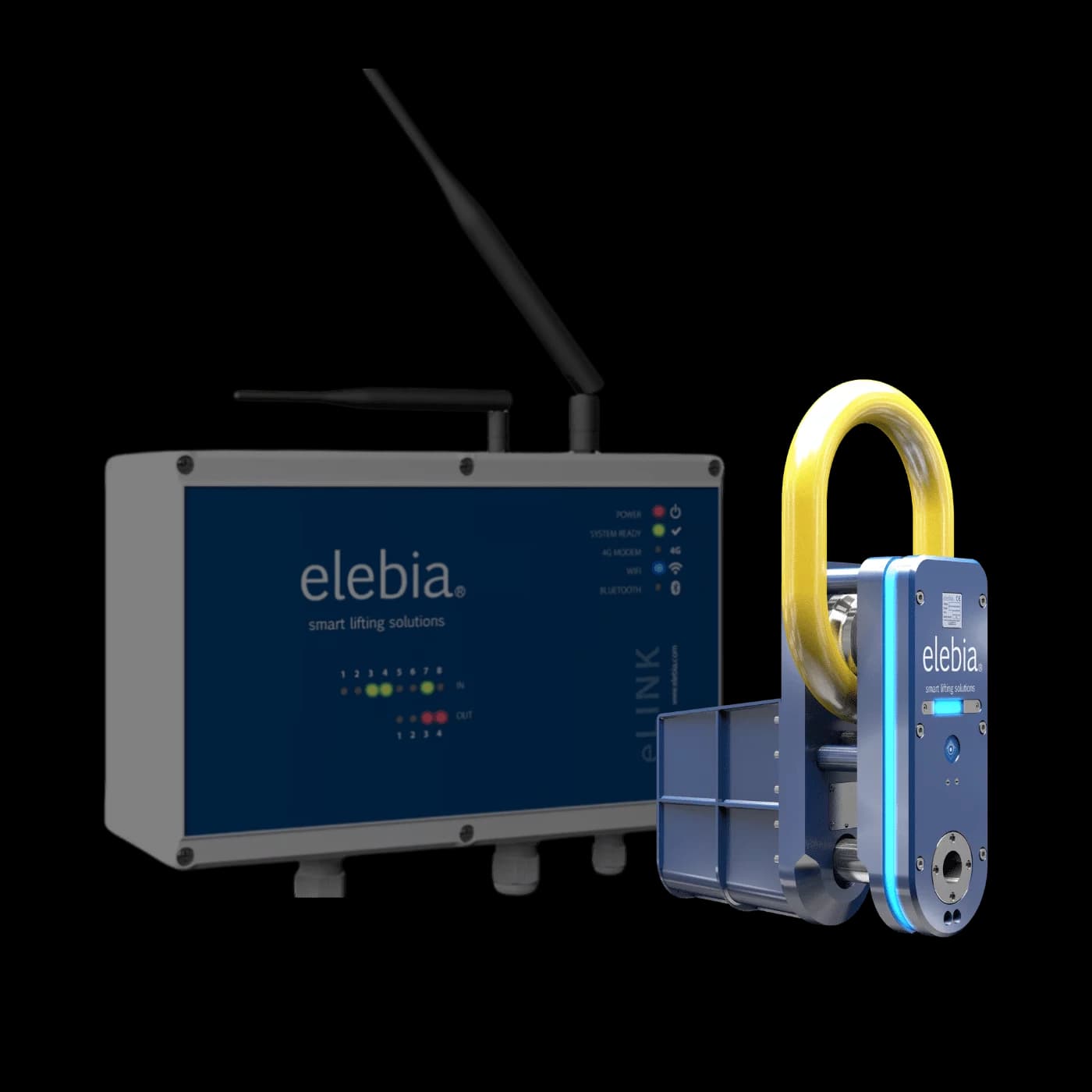

Remote Control Your Lifts: Wireless Convenience

The patented S40 Automatic Shackle is fully compatible with the eMAX, eMINI, and/or eINST remote controls. For optimal and safe use of the S40 Automatic Shackle, we strongly recommend pairing it with the eLink remote control device. When correctly configured, the eLink can block the crane's vertical movement while the shackle is in transition (signaled by red LEDs), minimizing the risk of hazardous situations and potential damage to the device.

Weighing scale: Optional Load Cell Integration for safer lifting

The S40 automatic shackle can be equipped with a load cell for precise load measurements during the lifting process. Our load cells provide quick and accurate readings, offering affordability and a longer lifespan compared to other sensors. Primarily used for weighing and preventing overloads, the load cell, when combined with the remote control, transforms our automatic shackle into a sophisticated and precise weighing scale with advanced features.

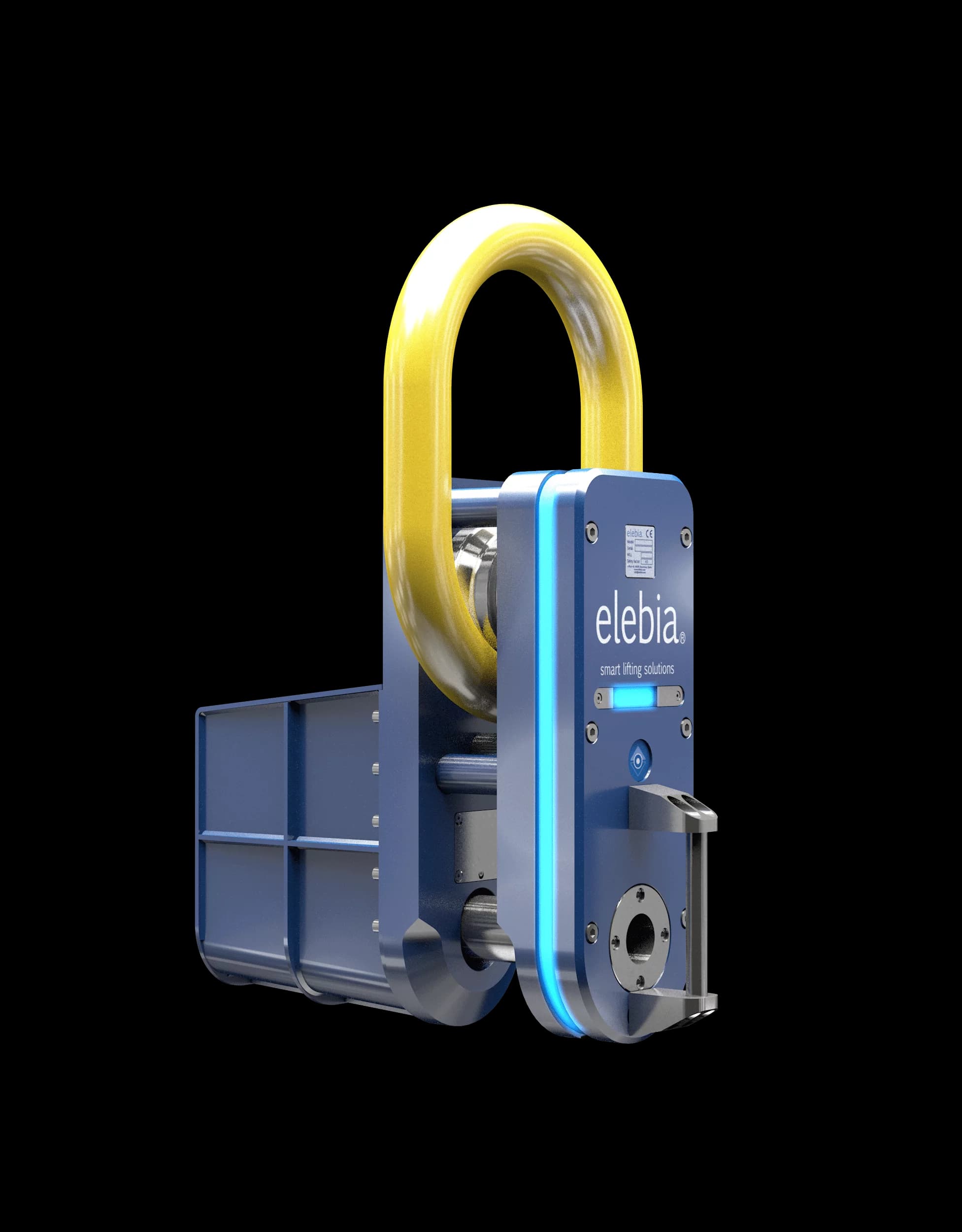

Versatile Lifting Solutions: Optional Finger Accessory

The automatic shackle's “finger” is the first component to contact the lifting point, stabilizing the automatic shackle, stopping any crane swing, and helping position it with precision.

Comfortable and Secure: Optional Handle

Handle for improved ergonomics.

Frequently Asked Questions

What makes the S40 shackle different from traditional crane shackles?

The S40 automatic shackle is automatic and remotely controlled, providing improved safety and operational flexibility.

What maintenance is required for the S40 Automatic Shackle?

Regular inspection and adherence to Elebia's maintenance guidelines will ensure the shackle remains in optimal condition.

Can the S40 shackle be customized for specific lifting needs?

Yes, Elebia offers customization options to meet specific lifting requirements with the S40 automatic shackle.

What is the delivery time for the S40 Automatic Shackle?

Contact Elebia's sales team for up-to-date delivery information.

How does the fail-safe design of the S40 automatic shackle ensure load safety?

The fail-safe design prevents accidental release, securing the load during lifting.

Can the S40 shackle be used in extreme weather conditions?

Is built to withstand harsh weather, providing reliable performance in challenging environments.

Features

Features

Automatic engage and release of load

Safety factor of 4:1

Fail-safe design

Autoclose system

Upgradeable with a load cell

Battery powered and remote controlled

Working Load Limit (WLL): 40,000 kgs / 88,184 lbs

For openings over 50mm Ø

LED status indicator

Plug and play

Videos

Controlled and Secure Lifting with S40

Controlled and Secure Lifting

Effortless Alignment with the Elebia S40 Autoclose System

Specifications

- Regulatory Standards

EN 10204 3.1.B

UNE-EN 61000-6-2:2006

D89/654/EEC

UNE-EN 1050

UNE-EN ISO12100:2012

D89/655/EEC

UNE-EN 60204-1:2007

UN 38.3

D89/656/EEC

UNE-EN 61000-6-4:2007

D89/391/EEC

D92/58/EEC 9a

Directive on Machine Safety (D2006/42/EC).

EMC Directive (2014/30/EU).

Low Voltage Directive (2014/35/EU).

Radio Equipment Directive (2014/53/EU).

Assurance of Production Quality in accordance with ISO9001.

ARIB Construction Design Certification Number 203-JN0689.

FCC Identifier 2ACLHEVO for Equipment Class: Digital Transmission System.

Each mechanism is delivered with the CE stamp and a declaration of CE conformity.

Elebia is a member of F.E.M. (European Federation of Materials Handling).